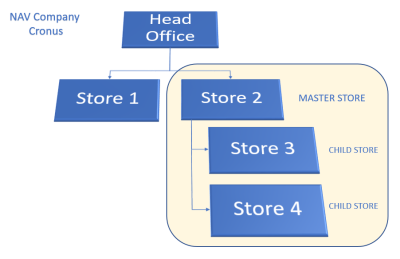

The goal of the Master Child Replenishment is to provide a solution to calculate Replenishment Journals in an environment with stores that operate as stock buffer for other stores. This is also commonly known as store-in-store concept.

This scenario is common and is usually seen when one Master store is the entity for replenishment and it feeds Child stores.

- A Master store holds one or more stores, and item replenishment is only done and received at the Master store.

- The Master store sells items and receives items from the warehouse or vendor using standard replenishment calculation approach.

- The Master store's demand, stock, and so on, is the total of its own and also from the assigned Child stores.

- The Child stores sell items and receive the items via transfer orders from the Master store. Transfer Orders are created manually and are NOT part of the solution.

Figure 1: Store 2 is a Master Store, Store 3 and Store 4 are its Child stores.

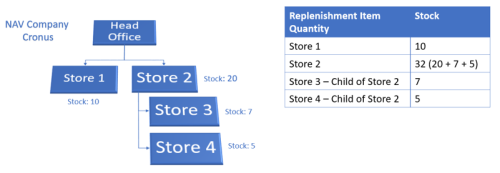

The Replenishment Item Quantity calculation is performed for all stores, but the Replenishment Item Quantity of the Master store will contain the aggregated information (for example, Inventory and Quantity on Purchase Order) from its own and also from its assigned Child stores. Only the Master store will be considered for Replenishment Journal calculation.

Figure 2: Calculation of Replenishment Item Quantity for Master and Child stores.

| To | See |

|---|---|

| Set up Master Location for Child location. | Location Setup |

See also