Replenishment can be run with multiple warehouses. In such cases the stores will be supplied from those warehouses or directly from vendors, if set up accordingly. Rules are needed to assign stores to warehouses - this is covered in the Item Flow process step.

Goal

The goals of this step:

- Get a detailed understanding of the retailer's company structure and the warehouse structure

- Create a topology drawing or a list of warehouses

- Set up warehouses in LS Central.

Output

LS Central setup considerations

Location

The relevant locations have to be created and set up as warehouse locations.

The Location is a Warehouse check box on the Location card must be selected:

For more details see Location.

Replenishment Setup

One warehouse location has to be set up as the default warehouse location in the Default Central Warehouse field on the Replenisment Setup page:

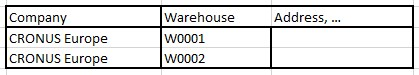

All stores will be replenished from this warehouse, unless defined differently in the Replen. From Warehouse page:

For more details see Warehouse.

Replenishment rules for non-default warehouses

For the non-default warehouses, explicit definitions must be set up: which store will be replenished by which warehouse for which items. This is analyzed in detail in the Item Flow process step.

Replenishment Templates

Purchase Replenishment Templates are used to calculate Purchase Order proposals for the warehouse.

The templates need to have the value One Purchase Order per Vendor or One Purchase Order per Vendor with Cross Docking set up in the field Purchase Order Type:

For more information about Replenishment Templates see Replenishment Template.

Transfer Replenishment Templates are used to calculate Transfer Order proposals for the stores.

The templates need to have the warehouse location code set up in the Location Code field:

For more information about Replenishment Templates see Replenishment Template.

Go back to: