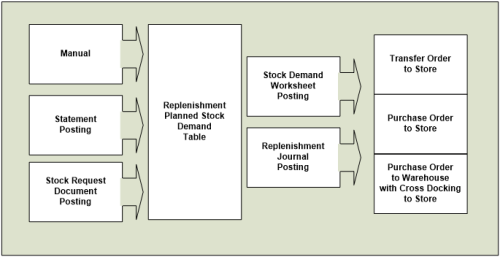

The Replenishment Planned Stock Demand table contains stock demand records for the stores.

Stock Request document posting

Replenishment Stock Demand Worksheet

Replenishment Journal – Add Item to Journal

Replenishment Planned Stock Demand records can be created:

- Manually in the Replen. Stock Demand Worksheet or in the Planned Stock Demand under the Item Card.

- As products of Statement posting where the item has the Replenishment Calculation Method Like for Like

- As products of Stock Request Documents

There are two ways of changing Replenishment Planned Stock Demand records to Purchase or Transfer Orders:

- By posting the record in the Replenishment Stock Demand Worksheet form.

- As input to the Replenishment Journal Batch job.

Note: Planned Stock Demand is not applicable to BOM and Component Replenishment Journals.

Statement posting

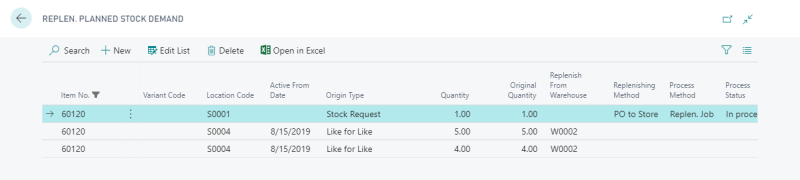

When a statement is posted the system creates a Replenishment Planned Stock Demand record for all items with the Replenishment Calculation Method Like for Like in the Statement Lines. The record gets the default value from the Replenishment Data for the fields Like for Like Replen. Method and Like for Like Process Method.

Example:

If the Replenishment data fields contain:

- Like for Like Replen. Method = PO to Store

- Like for Like Process Method. = Replen. Job.

This means that records with these values are created in the Replenishment Planned Stock Demand table. The next step is when you run a Replenishment Journal of the type Purchase Order to Store. The records are included in the process and the item is ordered from the vendor and delivered to the store directly.

There is a report process that looks through all posted statements and processes statements that have not been processed.

To access the report:

-

Click the

icon, enter Replen. Upd. Like-for-Like, and select the relevant link.

icon, enter Replen. Upd. Like-for-Like, and select the relevant link.or

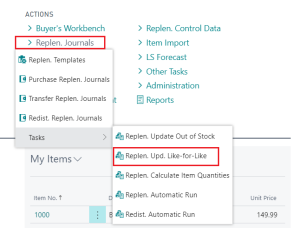

- Use Actions in the Replenishment Role Center as shown in the image below:

The report Replen. Upd. Like-for-Like goes through all posted statements and checks if the statement has been processed (if there is a record in table Replen. Like-for-Like Stmt.), and if not, it creates Replenishment Planned Stock Demand records for the items with the Replenishment Calculation Type Like for Like.

Stock Request document posting

The posting of a Stock Request documents can create Replenishment Planned Stock Demand records.

By selecting the Replenishment Batch Job option, you will create Replenishment Planned Stock Demand records that become an input in the next Replenishment Journal run of the selected document type.

To include the lines in the next Replenishment Journal of the type Transfer Order for the store, select Transfer Order from Document Type and Replenish as Process Type.

When you select Purchase Order as the Document Type, you can choose between having the Purchase Order delivered directly to the store or to have it delivered to the warehouse and then cross docked by a Transfer Order to the store.

The above image shows a processed Replenishment Planned Stock Demand record.

Replenishment Stock Demand Worksheet

The Replenishment Stock Demand Worksheet page lets you add, modify, or create Replenishment Planned Stock Demand records manually.

You can use filters to select the records to work with, and perform the actions of Create Transfer(s) or Create Purchase Order(s).

All records with blank Vendor No. or Replenish. From Warehouse fields are not processed and are left behind while the Purchase Orders and Transfer Orders are created.

Note: It is possible to specify the Active From Date for the record, and it will not be valid for replenishment jobs until the specified date is reached.

Replenishment Journal – Add Item to Journal

The Add Item to Journal function in the Replenishment Journal inserts a line in the Replenishment Journal lines according to the Replenishment Journal Template. The job will first go through all valid Replenishment Planned Stock Demand records and add them to the journal if there is enough stock. The process will then go through the rest of the Replenishment Calculation Method, for example Average Usage, Manual Estimate and Stock Levels.