A bill of materials (BOM) is a product that consists of multiple items, and these items that are needed to create the BOM are known as components. In the food and beverage sector within the hospitality industry, a BOM is more commonly known as a recipe and the components are the ingredients that make up the recipe.

Assembly Orders for BOM in BOM

Put Creation of Assembly Orders on Batch Posting Queue

You can perform the replenishment calculation of the BOM and components with a two-step approach by using the BOM Replenishment Journal and Component Replenishment Journal. When the BOM Replenishment Journal is calculated and you are satisfied with the result, you can execute the Create Assembly Orders function to create Assembly Orders for BOM items that are assigned with BOM Method Produce.

The Assembly Orders from the BOM Replenishment Journal can either be created to have the BOM items assembled in the warehouses, or in the stores. Depending on the Purch. Order Delivery and BOM Assembled In settings of the BOM items, the Assembly Orders can either be created in the BOM Purchase Replenishment Journal or BOM Transfer Replenishment Journal. There are three possible scenario:

-

Condition: Purch. Order Delivery = To Warehouse, BOM Assembled In = Warehouse

Result: One Assembly Order will be created per BOM item in the BOM Purchase Replenishment Journal for the relevant warehouse. -

Condition: Purch. Order Delivery = To Warehouse, BOM Assembled In = Store

Result: One Assembly Order will be created per BOM item and per store in the BOM Transfer Replenishment Journal. -

Condition: Purch. Order Delivery = To Store

Result: One Assembly Order will be created per BOM item and per store in the BOM Purchase Replenishment Journal.

Only Replenishment Journal Detail lines with their Create Assembly Order field selected will be considered for Assembly Order creation. Once the BOM Replenishment Journal is calculated, this field is automatically selected for all the Replenishment Journal Detail lines that are qualified for Assembly Orders creation.

While the Assembly Orders are usually created manually, it is possible to let the system create the documents automatically after the calculation in the Journal. This can be set up by selecting the value Create Orders Automatically for the Create Orders Automatically field on the Replenishment Template page for the BOM Replenishment Journal. This is used when executing the Replenishment Journal process as an overnight Scheduled Job.

Assembly Orders for BOM in BOM

When an Assembly Order is created, the BOM item and its related information, such as the quantity to assemble, will be created in the Assembly Header. On the other hand, information related to the components required to construct the BOM are populated in the Assembly Lines. There are scenarios where a component is also made up of multiple items, and such component is known as BOM in BOM. When a BOM in BOM exists, its Assembly Line is not exploded into its individual components, instead, a separate Assembly Order will be created for the BOM in BOM, with its components and their required quantities in the Assembly Lines. The Item No. of the parent BOM is appended to the Description field of such an Assembly Order, to make it easier for you to identify the originating BOM of the BOM in BOM item.

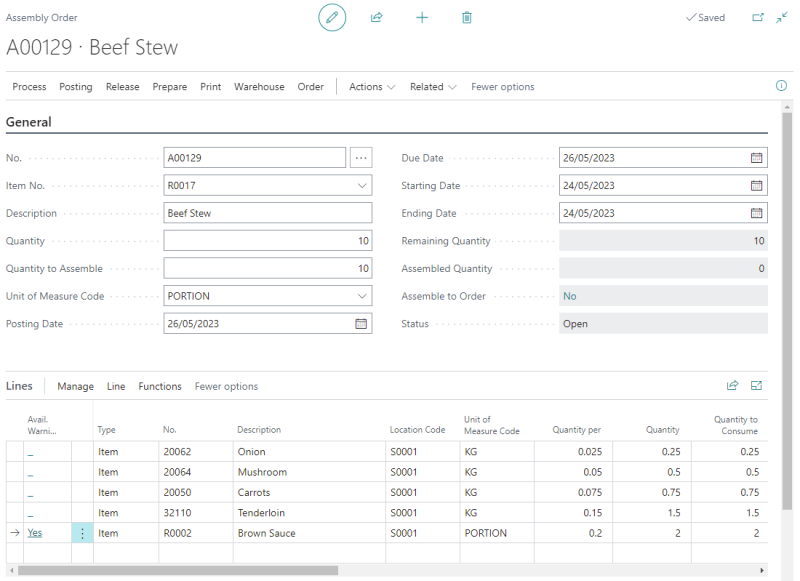

For example, to produce 10 portions of BOM item Beef Stew requires the following ingredients:

- 0.25 kg of Onion

- 0.5 kg of Mushroom

- 0.75 kg of Carrots

- 1.5 kg of Tenderloin

- 2 portions of Brown Sauce

The Assembly Order for Beef Stew will be created as shown below. Note that Brown Sauce is a BOM in BOM and its Assembly Line is not exploded into its individual components at this stage.

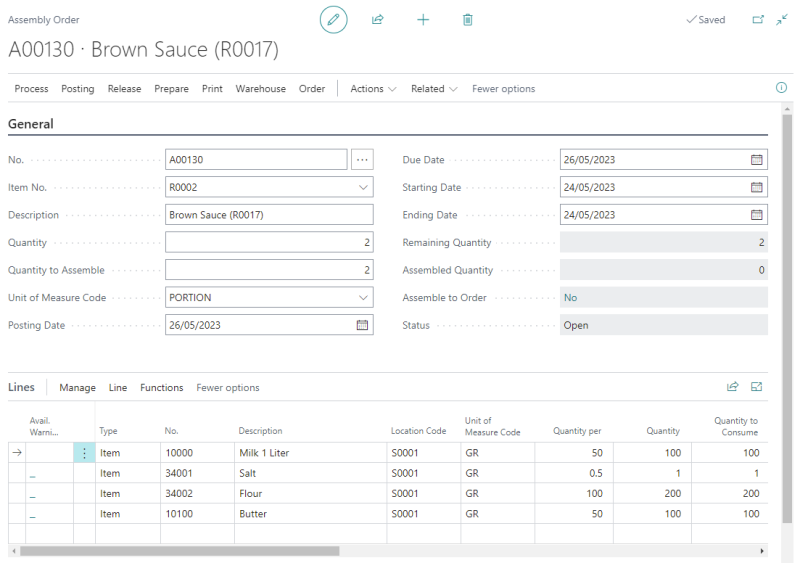

A second Assembly Order is created for Brown Sauce with the required portions, and its components populated in the Assembly Lines. The Item No. of Beef Stew (the originating BOM) is appended to the Description field of the Assembly Order, in round brackets.

Put Creation of Assembly Orders on Batch Posting Queue

The function of Creation of Assembly Orders on Batch Posting Queue is to allocate the document creation request to the Batch Posting Queue to be created by the Batch Posting Queue process.

Order Documents Release

It is possible to have the system automatically release the Assembly Order document after it is created from the BOM Replenishment Journal. This can be set up with the Release Assembly Order After Creation field on the Replenishment Template page for the BOM Replenishment Journal. This field is also available on the Replen. Setup page and the global setup will automatically apply to any newly created Replenishment Template.

Multi-Company Replenishment

In Multi-Company Replenishment environment, no Assembly Orders will be created from the BOM Transfer Replenishment Journal in the supply chain company, if the destination locations reside in the sales companies.

The Assembly Orders should be created from the BOM Transfer Replenishment Journal in the respective sales company.

See also